The Future of Energy Efficiency Starts Here

Spray foam insulation isn’t just for construction nerds or eco-warriors — it’s for anyone who wants a home or building that’s quieter, more comfortable, and drastically cheaper to heat and cool. Whether you’re upgrading your home, planning a renovation, or curious about energy-saving solutions, understanding spray foam insulation might just change the way you think about your space.

Understanding Spray Foam Insulation

Spray foam insulation is a modern, high-performance material made by mixing two chemicals — isocyanate and polyol resin — that react to create a foam. This foam rapidly expands on contact, filling cracks, gaps, and cavities to form a durable barrier that resists heat flow and air infiltration.

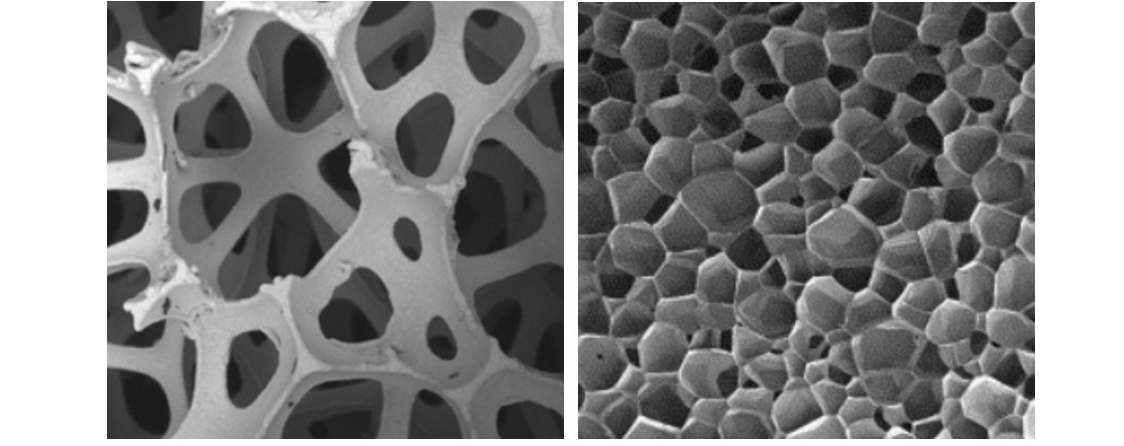

There are two primary types:

- Open-cell spray foam: Light, flexible, and spongy, this version is ideal for interior use. It provides strong sound absorption and a lower R-value (insulating power) per inch.

- Closed-cell spray foam: Dense and rigid, it offers a higher R-value and acts as a vapor barrier. It’s commonly used for exterior walls, basements, and roofs.

“Think of it as insulation and sealant in one. It’s not just a filler — it’s a complete envelope,” explains Tom Keller, a certified energy auditor.

Common Uses in Residential and Commercial Spaces

Spray foam insulation is one of the most versatile insulation materials on the market. It can be applied to:

- Attics and lofts

- Interior and exterior walls

- Basement and crawl spaces

- Garage ceilings

- Roofs and underflooring

- Gaps around windows, doors, and pipes

Its ability to mold to any shape makes it perfect for irregular spaces and hard-to-reach areas — something traditional batts or rolls just can’t achieve.

Spray Foam vs Traditional Insulation: A Clear Winner?

Let’s break it down:

- R-Value (per inch)

- Spray Foam: High (6–7)

- Fiberglass/Cellulose: Medium (2.2–3.8)

- Air Sealing

- Spray Foam: Excellent

- Fiberglass/Cellulose: Poor

- Moisture Resistance

- Spray Foam: High (especially closed-cell)

- Fiberglass/Cellulose: Low

- Longevity

- Spray Foam: Lasts for decades without settling

- Fiberglass/Cellulose: May sag or settle over time

- Soundproofing

- Spray Foam: High (notably with open-cell)

- Fiberglass/Cellulose: Moderate

- Installation

- Spray Foam: Requires professional installation

- Fiberglass/Cellulose: DIY-friendly

Spray foam acts like a thermal jacket for your building. It blocks not only heat but also air and moisture, making it a triple-threat in building science.

Benefits That Go Beyond Comfort

So why should the average homeowner or builder care? Because the advantages are measurable — and meaningful.

- Lower Utility Bills: Energy savings of 20–50% are common thanks to superior sealing and insulating properties.

- Better Indoor Air Quality: By reducing air leaks, it helps keep allergens, dust, and pollutants out.

- Mold Prevention: Closed-cell foam resists moisture, which deters mold growth.

- Noise Reduction: Especially with open-cell spray foam in walls and ceilings.

- Increased Structural Strength: Closed-cell foam adds rigidity to walls and roofs.

- Sustainable Living: Reduced energy use = lower carbon footprint.

“We started saving over $100/month on our utility bill after switching to spray foam,” says homeowner Maria Thompson. “And our home is noticeably quieter too.”

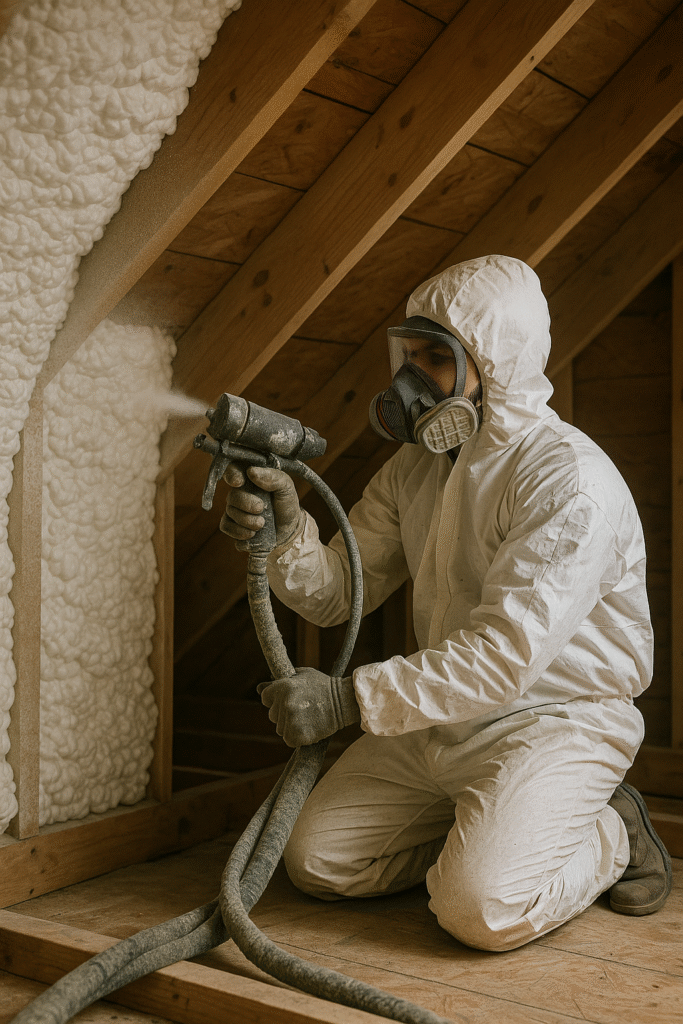

The Installation Process: Step by Step

Spray foam insulation should always be handled by trained professionals due to chemical exposure risks and the need for precision. Here’s what to expect:

- Consultation & Quote: A contractor assesses your property and suggests appropriate solutions.

- Prep Work: Surfaces are cleaned, and areas are masked off.

- Application: Using a spray rig, the foam is applied in layers and left to expand and cure.

- Curing Time: The foam hardens in minutes, but the space may require ventilation for 24–72 hours.

- Final Inspection: Technicians inspect for proper coverage and sealing.

Safety Tip: Occupants should vacate during installation and curing. Proper ventilation and PPE are critical during this process.

Things to Consider Before You Commit

While spray foam offers significant advantages, it’s not a one-size-fits-all solution. Consider the following before moving forward:

- Cost: Expect to pay $1.50–$3.00 per square foot for open-cell and $3.00–$6.00 for closed-cell — higher than traditional methods, but often recouped in savings.

- Retrofits May Require Demo: Installing in existing walls can be tricky without drywall removal.

- Not Always Eco-Friendly: Some foams use chemical blowing agents; ask about low-GWP (Global Warming Potential) options.

- Professional Installation Required: DIY kits exist, but most experts advise against them due to safety and quality risks.

A Smart Investment for Homeowners and Builders Alike

When you factor in energy savings, improved comfort, better air quality, and long-term durability, spray foam insulation becomes more than a trend — it’s a long-term solution for a sustainable, efficient, and livable space.

Whether you’re designing your dream home or upgrading an older one, spray foam can dramatically change how your property performs year-round.

“Insulation is one of the few upgrades that pays for itself — and spray foam does it faster than most,” notes building contractor James Ellis.