Making the Right Insulation Choice for Your Structure

Not all spray foam is the same. When planning an insulation project, you’ll encounter two main options: open-cell and closed-cell spray foam. While they look similar at first glance, they serve very different purposes. The wrong choice can lead to performance gaps or unnecessary costs.

This comparison breaks down the differences so you can select the best type for your needs.

What Is Open-Cell Spray Foam?

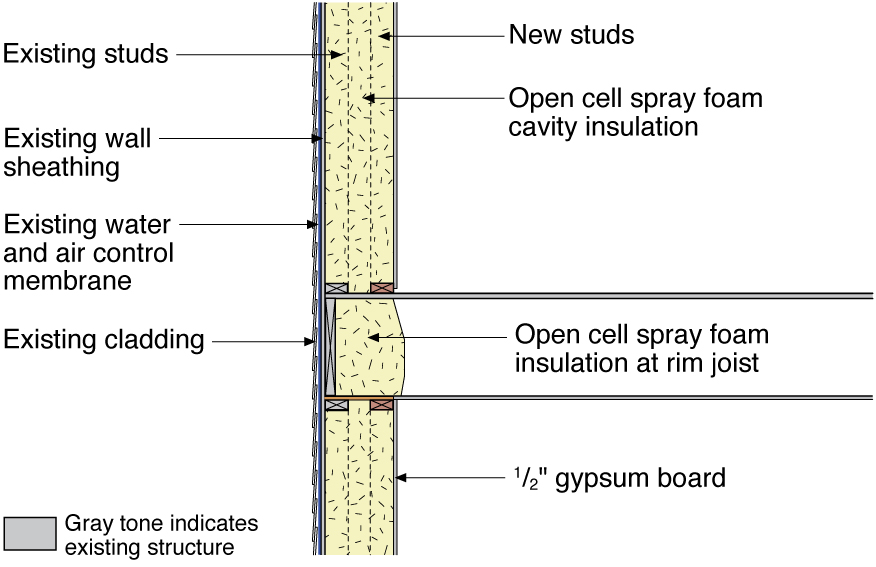

Open-cell spray foam is made up of tiny cells that are left intentionally open. This makes the foam softer, lighter, and more flexible. It expands significantly when applied, making it ideal for filling wall cavities and tight spaces.

Key traits:

- Density: ~0.5 lb/ft³

- R-value: ~3.6–3.8 per inch

- Vapor Permeable: Yes

- Sound Absorption: Excellent

- Air Barrier: Yes (at sufficient thickness)

- Water Barrier: No

- Cost: Lower

Best for:

- Interior walls and ceilings

- Soundproofing rooms

- Projects where budget is a primary concern

What Is Closed-Cell Spray Foam?

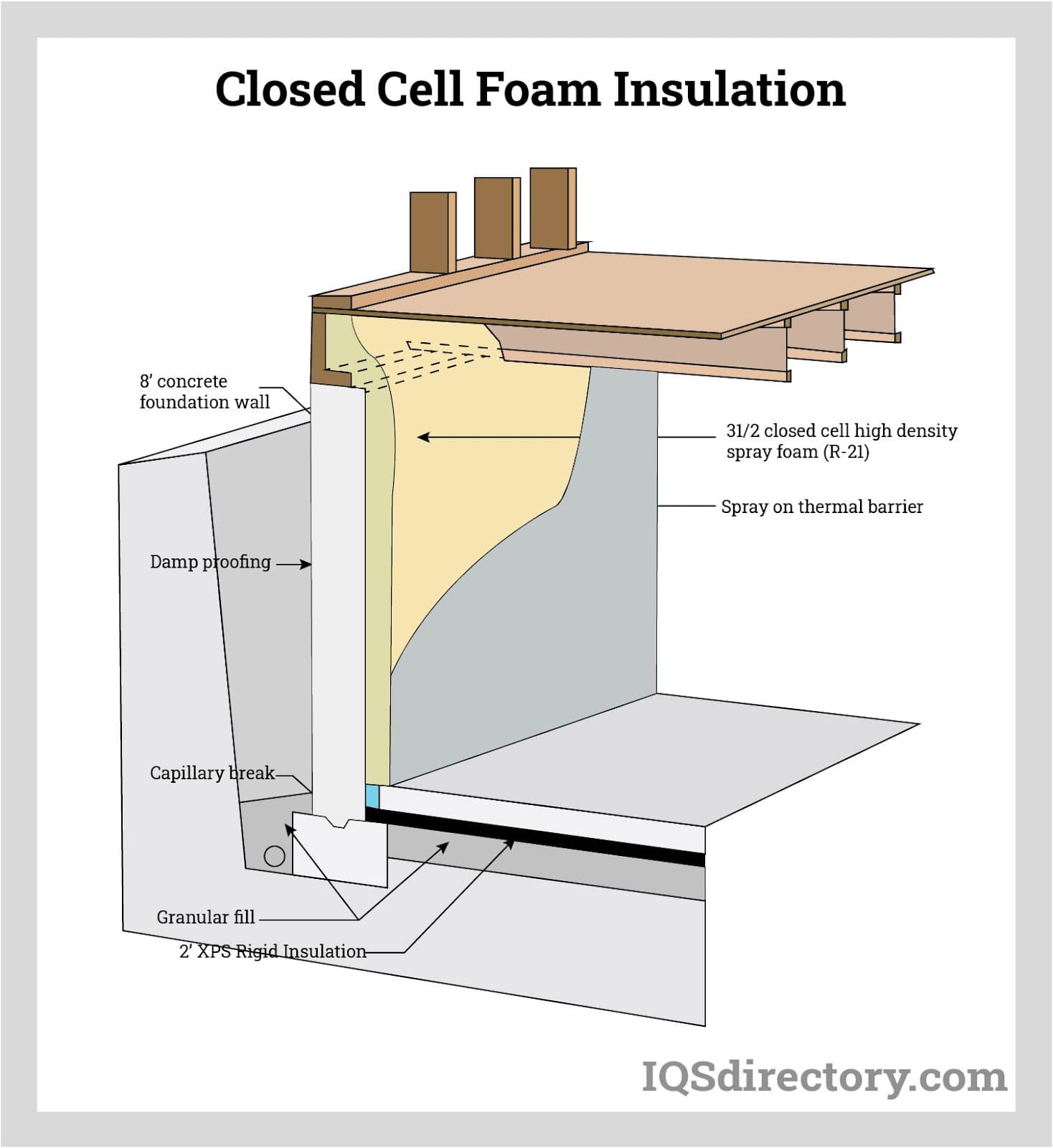

Closed-cell foam has a compact cell structure that makes it rigid and impermeable to moisture. It offers a higher R-value and can even add structural strength to buildings. Closed-cell is the go-to for areas exposed to moisture or where maximum thermal resistance is needed.

Key traits:

- Density: ~2 lb/ft³

- R-value: ~6.0–7.0 per inch

- Vapor Barrier: Yes

- Moisture Barrier: Yes

- Structural Support: Yes

- Cost: Higher

Best for:

- Exterior walls and roofs

- Crawl spaces and basements

- Commercial and industrial buildings

- Areas prone to moisture or flooding

Side-by-Side Comparison

- R-Value per Inch

- Open-Cell: ~3.7

- Closed-Cell: ~6.5

- Expansion Rate

- Open-Cell: Expands up to 100x

- Closed-Cell: Expands up to 30x

- Moisture Resistance

- Open-Cell: Minimal

- Closed-Cell: High

- Soundproofing

- Open-Cell: High

- Closed-Cell: Moderate

- Application Cost

- Open-Cell: Lower

- Closed-Cell: Higher

- Vapor Barrier

- Open-Cell: No

- Closed-Cell: Yes

- Structural Rigidity

- Open-Cell: Flexible

- Closed-Cell: Adds strength

Choosing Based on Climate

In humid or flood-prone areas like the Southeastern U.S., closed-cell foam is usually the better choice due to its moisture barrier properties.

In drier, moderate climates or in projects where air sealing and soundproofing are the main goals, open-cell foam may be more cost-effective and suitable.

When to Combine Both

Some projects benefit from using both types of spray foam. For example:

- Closed-cell in crawl spaces and basement walls

- Open-cell in interior partition walls for sound dampening

- Closed-cell on the roof deck

- Open-cell in accessible attic knee walls

Talk to your insulation contractor about hybrid solutions tailored to your building.

Final Thoughts

Both open-cell and closed-cell spray foam provide excellent insulation and air sealing. The key is matching the material’s properties with your project’s specific performance needs. Whether you prioritize sound control, moisture defense, or structural enhancement, understanding these differences ensures you make a confident, informed decision.